Diagnostics with fault code messages are definitely over in the " troubleshooting" field. The last nail in its coffin has been hammered in by artificial intelligence (AI), which we are now teaching to search for inspiration in the algorithms we compile ourselves in the FCD Garage.

Example of classic diagnostics

The Audi diesel car fault code message reports "SCR catalytic converter efficiency too low". Replace? NO!

If we look at the live readings from the test drive, the NOx values after the SCR catalytic converter are higher than in front of it! Does the SCR catalyst produce NOx on its own, when it is supposed to reduce them?

All manufacturers have such flaws in their diagnostics and as a result parts are replaced unnecessarily. Nobody will pay the workshop for the mistakes caused by the classic diagnostics. Without the workshops influence, the unreliable fault code messages only spoil the workshops reputation.

The story presented below is about a petrol car and demonstrates, as another example of the countless number of claimed faults, the inability of vehicle manufacturers to capture faults on complex systems using "Trouble Codes". This is no longer effective enough for the chained responses of other systems and overlooks the failure of a genuinely defective part. In fact, most systems have long been working with so-called "adaptives" (adaptations) and these can conceal all the normal symptoms known to date. The mechanic can no longer recognise them either.

By long-term observation of a community of service technicians, diagnosticians and mechanics from car repair shops focused on fault diagnostics, we mostly registered one type of help request.

Statistics are unforgiving, and this has been the most common question asked by mechanics over the past five years when they've reached the stage where any advice is good advice when it comes to searching for a harder-to-identify fault.

Recording data, known in our terminology as "logging", is more efficient than fault codes themselves. We have evidence that logging outperforms them in many ways, and there are thousands of them here on the portal without exaggerating. For example, the EGR valve stays open on a petrol engine, and while the control unit reports "mixture too rich", the Log reveals the actual truth from the "airflow" and "injected fuel quantity" parameters, i.e. that the mixture is being unreasonably leaned out just because the Lambda sensor is reporting low oxygen (see detailed description below).

We are not referring to the almighty, but to the IT term "Cloud". Automation of diagnostic processes is nowadays developed on this Internet platform, which significantly helps the car mechanics. Thanks to the FCD Cloud, the mechanic is able to obtain text-based help, which is the result of processing the initial log using pre-programmed algorithms.

In the text-based help, where the sentence composition is provided by artificial intelligence, the mechanic doesn't actually learn "what's wrong", but finds basic pointers for the next recommended steps, for example this:

This exhaustive but non-specific text-based help teaches the mechanic to think about systems so that he or she can understand the response and feedback sequences of other systems from the log graphs processed by the FCD Cloud algorithms . AI text-based responses will accompany the Logs in an even more sophisticated way, increasingly sophisticated way, because the rising number of diagnostic requests and their alternatives will make the answers more complex and will describe in more deatail specific actions on particular systems.

Faults often have hidden causes. The aforementioned binding EGR valve in a petrol engine will cause low oxygen content in the exhaust. This is detected by the Lambda sensor and the control unit will begin to lean out the injector valve injected quantity, thinking the mixture is too rich. It leans out the mixture so much that the leanest cylinder starts to misfire first, say, the third cylinder. In order to avoid damage to the catalytic converter, the control unit shuts off the injector on the most frequently misfiring cylinder and stores the fault code "Cylinder #3 misfire". A mechanic (even an authorised workshop!) comes in and starts the process of swapping spark plugs, injector valves, ignition modules and who knows what else. Note that at the start of this hardship there was only the slightly leaking EGR valve!

Now let's try to predict how it could look like with an automated diagnostic process that doesn't work with fault codes, but with the initial log recording after the adaptives were reset.

The algorithms of the FCD Cloud platform responsible for detecting abnormalities will find negative adaptives in idle and part-load modes. They will will return to zero as the load increases (throttle opens more). And since cylinder misfire "may" be a consequence of mixture leaning, the text generated by the result of this algorithm could look like this:

"Misfires are often the result of other causes. I have found negative adaptives of the mixture in the Log and I need to determine the reason.

The mixture adaptives are always based on information from the Lambda sensor. Negative adaptives always represent low oxygen content than normal in the exhaust gases.

Therefore, perform the following:

Keep in mind that some of the values interpreted by the control units are only theoretically calculated values. However, even the "measured" values may differ from the actual, e.g. due to the deviation of a defective sensor. The only and real truth is acchieved by measuring with an oscilloscope, and only by following all the rules described in our FCD Academy. Also use external exhaust gas test analyses in your diagnostics and follow our FCD Garage decalogue when troubleshooting. This is the only way to minimise the risk of ineffective analysis or that the repair will follow the incorrect path.

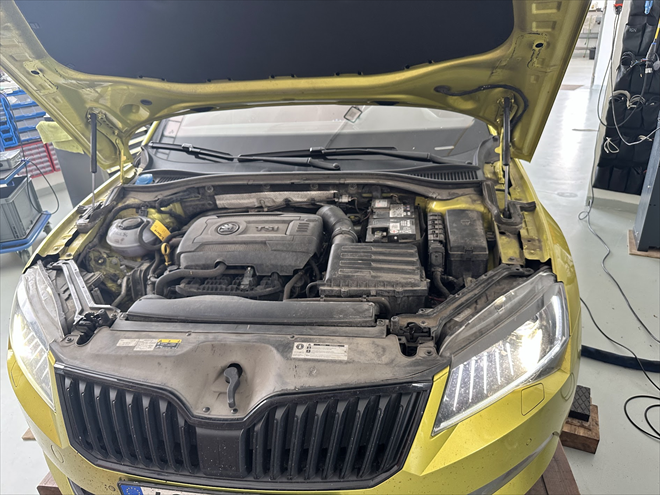

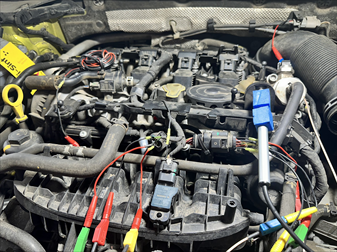

Join us to see how the first attempt turned out in reality.

There is no fault code in the fault memory and difficult warm starts of this type are known to be associated with contamination of the intake manifold with petrol vapour, e.g. from the fuel system ventilation (AKF).

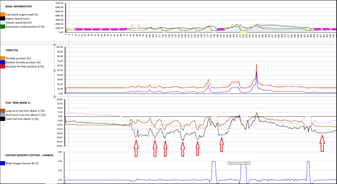

The black trace is generated by our application on the FCD Cloud and its tendency is important information for the algorithms generating AI help texts for the mechanic.

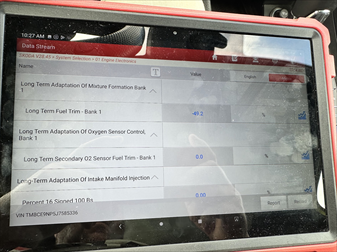

Here, the OEM diagnostics are showing the Long Term Fuel Trim value of almost –50 %!

Authorised ŠKODA workshops use a compulsory 2-channel oscilloscope, which is not capable of similar analyses.

This simple test cleared my mind that the intake was full of petrol vapours and therefore the engine struggled to start. Even when I purged the intake carefully with compressed air, the engine still started after a very long cranking period.

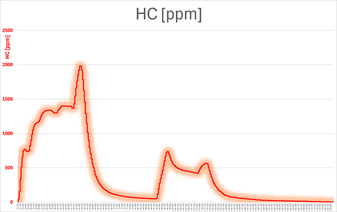

The crankcase ventilation is routed through channels in the cylinder head, so there is no way to disconnect it and simulate driving without ventilation to the intake system. But you can quickly see if there is petrol in the oil. With an exhaust gas analyser from the oil dipstick tube.

This is the exhaust gas analyser reading after inserting the sampling probe into the dipstick tube and then under the engine oil filler cap on a cold engine. In both cases, the reading is in the hundreds to thousands of ppm by volume, when it should be in the units, max. tens of ppm. Clear evidence that the engine oil is contaminated with petrol.

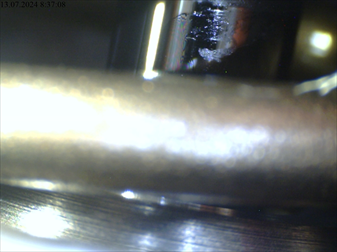

The piston of a high-pressure petrol pump is subject to abrasion and is lubricated only through micro clearances. Over time, the high pressure gasoline begins to enter the area of this stem and degreases it. As its lubrication capability is reduced, its surface begins to seize and leak more and more petrol into the oil sump, threatening virtually all lubricated areas on the engine with progressively increased wear and seizure.

"And how am I supposed to find out, dude, if I've plugged it in, dude, and it doesn't say anything, dude? Then come here and do it yourself, dude, if you're so smart, dude!

Robotic diagnostics behave exactly according to what the traces show and therefore has a great chance of not making things up, not making predictions, but stating the dry facts that result from the current constellation of all related traces on the timeline. In my personal experience, it's impossible to keep track of it all and sometimes you miss things even when you are at your best, rested and focused. That doesn't happen to robotic diagnostics.

Kompletní informace na toto téma

a mnoho dalších informací najdete pod odkazy níže.

Vyzkoušejte si nás nezávazně na 14 dní zdarma.

Vyzkoušet 14 dní zdarma

Komentáře (0)

Vložit soubor