- 3 Aktuální žádosti o pomoc Poraďte svým kolegům

- Požádejte o pomoc

- Podejte dotaz do fóra

- Vložit hotový případ

- LOG Decoder

Žádost o pomoc

Žádost o pomoc vyplňte, pokud máte rozpracovaný diagnostický případ na konkrétním vozidle, u kterého potřebujete pomoci zjistit skutečnou příčinu závady.

Pro naše nekonvenční metody je nutný základ znalostí a mít vlastní vybavení minimálně pro "logování", lépe však osciloskop. Nejlepší přípravou pro práci jsou naše videoškolení a akademie.

Jak to funguje?

Do online formuláře v jednotlivých krocích vyplníte všechny důležité údaje k případu a poté Vám ostatní registrovaní diagnostici poradí v komentářích*.

Supervizor a moderátoři FCD.eu samozřejmě vše doplňují a kontrolují správnost informací, aby cesta vedla ke správnému cíli.

Požádat o pomocDiagnostický případ

How I lost the battle

Informace o vozidle

| VIN: | TMBCE9NP5J7585336 |

| Výrobce: | Skoda |

| Model: | Superb III |

| Rok výroby: | 2018 |

| Kód motoru: | 2,0 TSI |

| Typ motoru: | CJXA |

| Výkon (kW): | 206 kW |

| Převodovka: | Automatická |

| Palivo: | Benzín |

| Najeto: | 201 074 km |

Jak se závada projevuje

Nefunguje / funguje nesprávně. After 20 minutes of shutdown, the car won't start. Only sometimes and randomly.

Jak často se závada projevuje

-

Sporadicky / za specifických podmínek.

- Za jiných podmínek. Once or twice a week, when the engine is hot and has been switched off about 20 minutes. Not any longer.

V jakém systému se závada vyskytuje

- Motoru.

- neukládá žádný chybový kód

Doposud provedeno bez úspěchu

The authorised Škoda dealer is unable to discover the fault by their means, when the car itself does not store any value in the memory. Their proposal is to replace parts one by one at the customer's expense. The customer expressed concern that the cylinder head could be cracked...Závěr

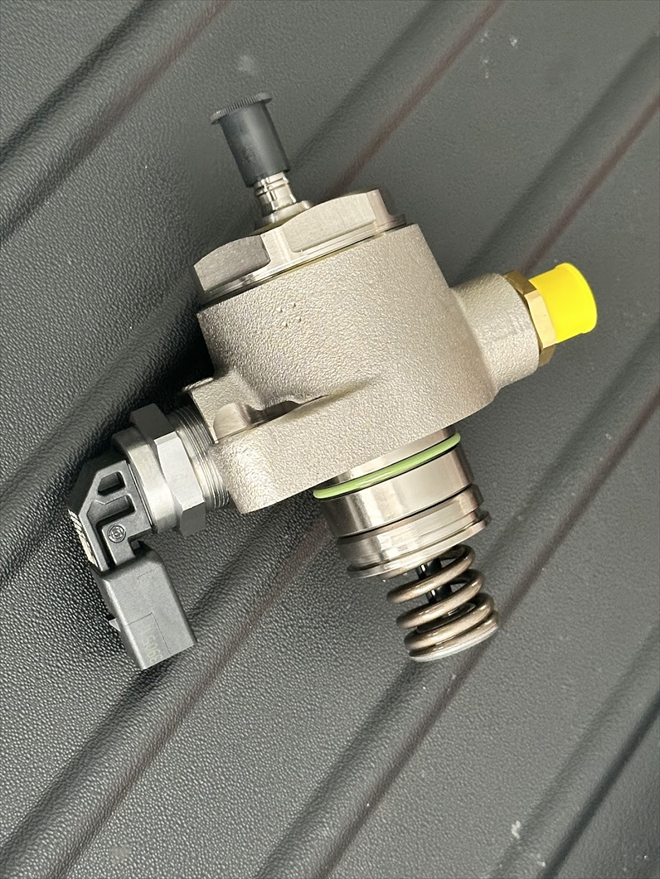

VOZIDLO JSEM OPRAVILProblem solved by replacing the high pressure pump (it was leaking). Gasoline was flowing into the oil pan after start up, from where it was vaporizing uncontrollably (temperature / loads / Tsi pressures...), basically when it wanted to and how intensely it wanted to.

If I had listened to the recommendation generated by the algorithm right from the initial log, I would not have stopped to check the misfires and test the MPi injectors.

But "intuition" is powerful and even if a person WANTS to suppress it, he cannot get rid of it and therefore includes unnecessary work. Algorithms are just suggestions that we should read, because they don't forget ANYTHING! Now as a "human", I just forgot. It won't happen to the algorithms, but then I have to read them too!

Just for the laughs, the new valve that I ordered was stuck in the open position, at maximum fuel flow. If it would have been installed on the engine and after switching the ignition On, the cylinder would be filled with fuel, with a risk of engine damage when the engine would be started. Luckily I installed the injector in an injector test/cleaning machine where the injector started working after a few minutes.

Note: Of course, the misfire was only a secondary effect. If the ECU reduces the injection time due to enrichment from the crankcase vapours, the valve works with the minimum (idle) injection time reduced by another 50%!!! The injection time is so short that the ratio of opening and closing time to full opening time is so high that the properties of the valve core return spring are reflected in the injected quantity of each valve. This causes greater variation between the individual injections.

Obrázky, fotografie a soubory

Randomly, once a week after the engine has been switched off for 20 minutes it won't start. (17825/1)

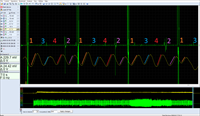

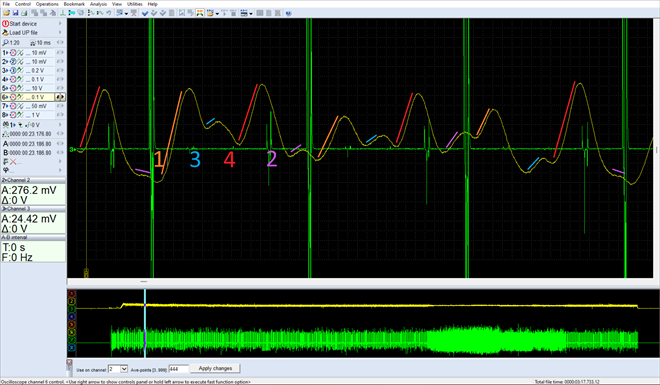

The engine starts and immediately stalls. On second attempt, the starter cranks a long time before the engine starts.Initial log with the FCD Logger , and immediately 2 faults (17825/2)

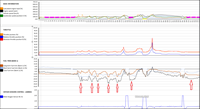

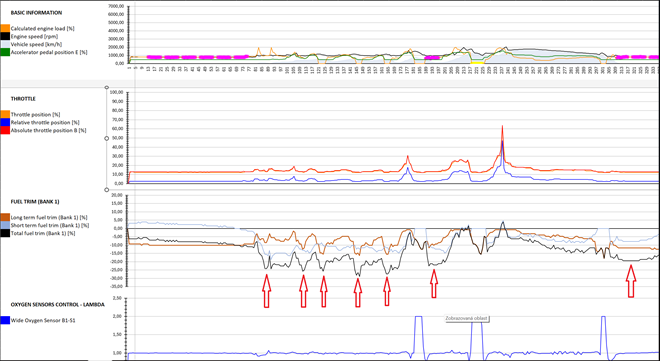

Here, where we have negative fuel adaptives of –30%, I experienced ignition misfires.If we allow the FCD Cloud algorithms to examine the log, the following text will be generated:

Negative mixture adaptives (mixture leaning) are a sign of low oxygen content in the exhaust gas (detected by the Lambda sensor). Check:

- The plausibility of the Lambda sensor signal (approx. 1 minute)

- Valve timing, (approx. 5 to 60 minutes)

- Injector valve leaks (approx. 20 minutes)

- Contamination of crankcase ventilation gases with petrol (approx. 5 minutes)

- Leaking of the AKF venting system valve (approx. 10 minutes)

- System fuel pressure (approx. 20 minutes)

- Correct injection valve types (approx. 20 minutes)

- Exhaust system clearance (approx. 20 minutes)

- Correct operation of the EGR exhaust gas return valve

- Measure the development of the exhaust emissions after all engine adaptives have been reset (approx. 30 minutes).

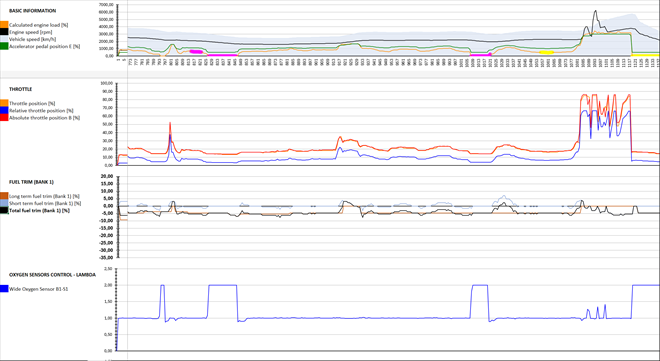

Adaptives while driving on a main rural road (17825/3)

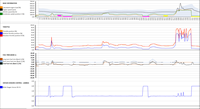

Stable driving conditions in rural area show standard adaptive fuel values, without any signs of problems with mixture control.About 3 - 5 minutes after a cold start misfires are present (17825/4)

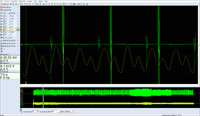

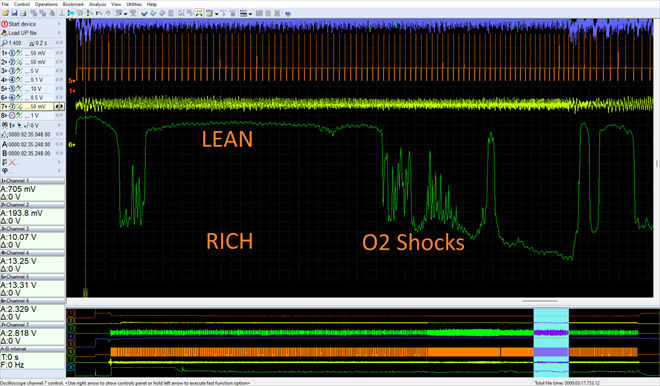

About 6 to 8 " slaps" from the exhaust tailpipe that repeat about 3 times with decreasing frequency. Then the engine runs relatively smoothly.At slightly increased idle misfire is present (17825/5)

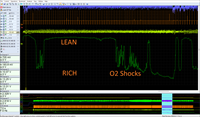

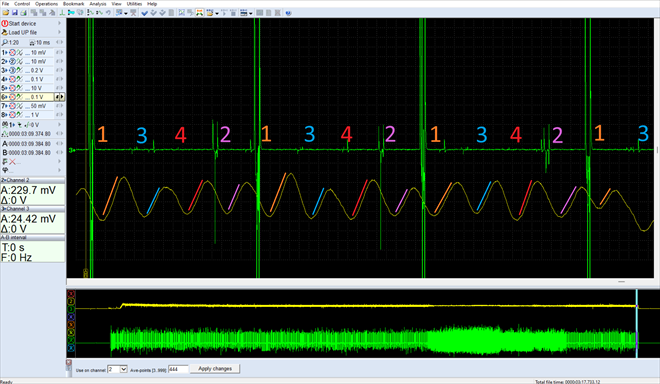

Oxygen shocks on the Lambda sensor signal. On some cylinders, sometimes the mixture doesn't ignite and the exhaust gases contain residue oxygen. (Note: This is a BBLS type Lambda sensor = inverse of step type Lambda sensor, so rich mixture is at the bottom, lean is at the top).Individual cylinder relative power (17825/6)

Misfire on cylinders #2 and #3, (measured on the alternator pulley) that generates lower kinetic energy.At a max. of 1 % time, the engine runs regularly (17825/7)

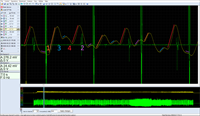

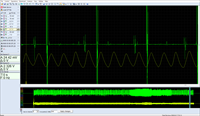

In 1% of the recordings, the engine runs relatively stable. Otherwise, you can see that the engine "kick in" on every other cylinder (stronger cylinder follows weaker one and so on and so on).The G-Sensor detects the engine shudder during misfire (17825/8)

Even the G-Sensor installed on the intake in the centerline of travel shows that cylinders #2 and #3 have about 2 minutes of misfire when the engine is still cold. Then the engine runs relatively stable.The G-sensor after engine warmup (17825/9)

As the engine warms up, the reaction movement of the cylinder block during the firing of the individual cylinders becomes relatively smooth.Test of 5 injector valves (#5 is new) (17825/10)

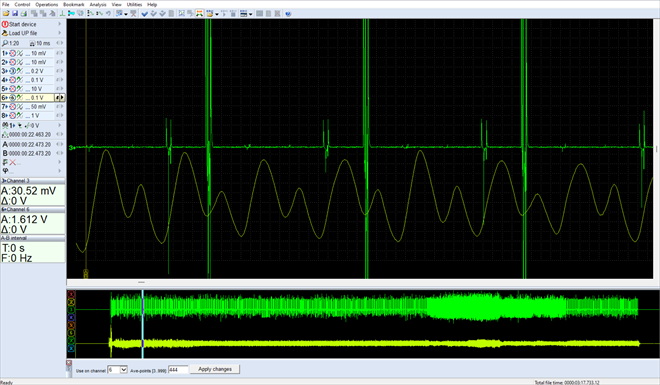

The injected fuel quantity is almost the same (the used test times were from about 1.8 to 5 ms).Ventilation of the intake manifold (17825/11)

By purging the intake manifold with pressurised air (dry compressor without oil), we ensured that the engine did not intake any petrol vapour. However, the subsequent start took a very long time and the engine was very reluctant to start, but with no known indications of starting a "flooded engine". The mixture was not rich, on the contrary, the engine did not have enough fuel at start-up.Idle/partial crankcase ventilation (17825/12)

The idle ventilation is not routed outside the engine. It flows through ducts in the cylinder head to all four intake branches, so you can't simply eliminate it (by disconnecting, and letting it vent to the atmosphere during a test drive). If fuel enters the oil in the sump (e.g. from a leaking high pressure pump), the engine pulls the fuel vapours from the oil into the cylinders after a short heating period through the intake manifold. The mixture is thus uncontrollably enriched in different intensity waves, depending on how much fuel currently enters the oil and how much is vaporized, (this depends on the oil temperature and the load).At the same time, the venting to the outermost cylinders #1 and #4 takes longer, and to cylinders #2 and #3, takes a shorter time, so more petrol vapors (if the oil is contaminated) will go to the middle cylinders #2 and #3.

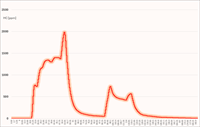

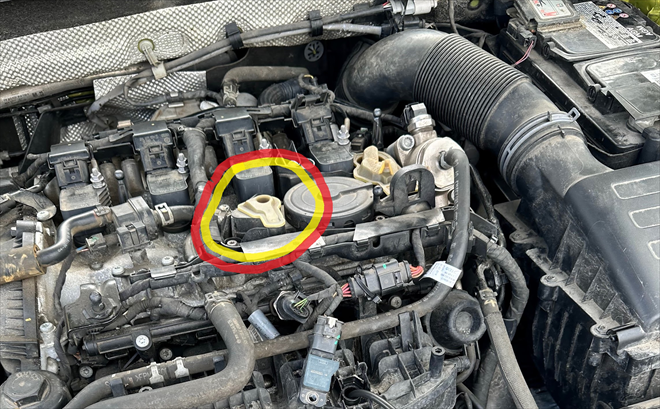

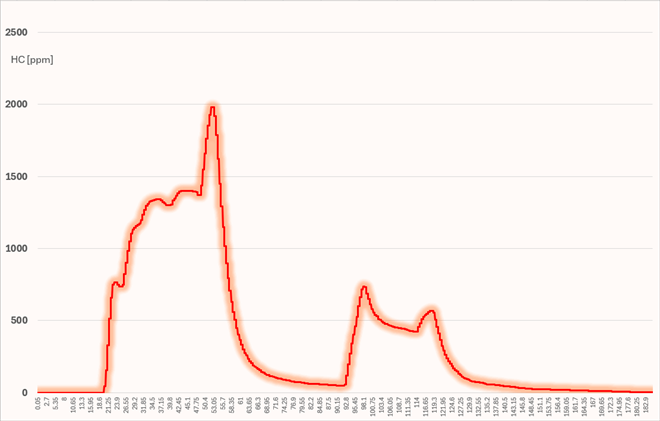

Petrol vapours in the crankcase after a short warmup period (17825/13)

The engine is not running, but has been briefly warmed up to approx. 60 °C The crankcase contains fresh petrol from a cold start. This is because the engine starts cold with the high-pressure direct injection system. A possible fuel leak into the engine oil during cold start will result in a large amount of fuel entering the oil, which will evaporate heavily as the engine temperature rises.Bingo – the oil is contaminated by petrol (17825/14)

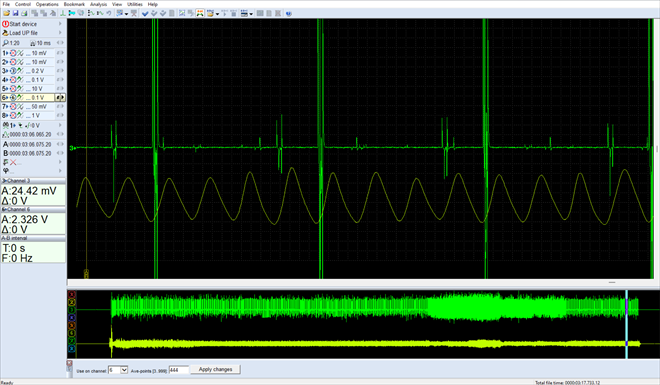

The first part is the reading from the oil dipstick tube, the second weighed values come from the measurement from under the oil cap (diluted by the draft).Cold engine after a two day shutdown. Oil does not evaporate, but gasoline does at room temperature. Expected around 20 - 200 ppm HC, but we measured 2000 ppm of hydrocarbons.

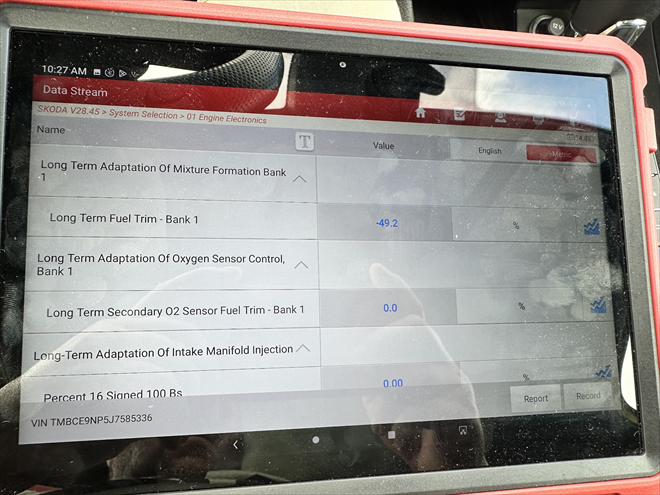

OEM diagnostics display several forms of adaptives (17825/15)

This adaptives show the trend of where the Long Fuel Trim adaptives provided by the EOBD protocol are slowly moving to. Misfire occurs when this adaptives approach the threshold (minus = lean mixture) – 50%!High-pressure pump (17825/16)

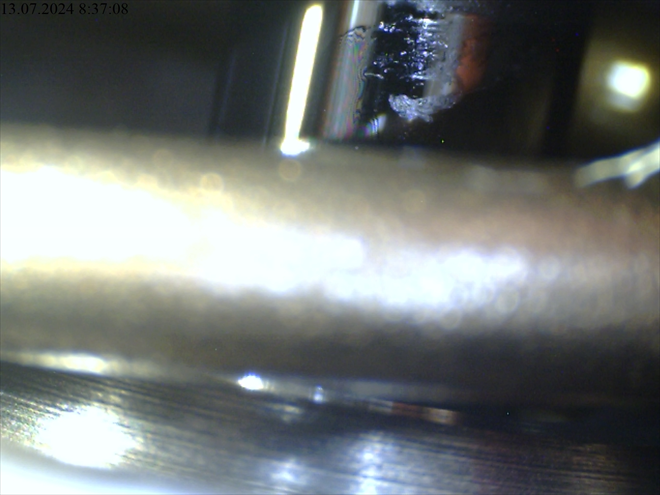

I ordered a high-pressure pump without inspecting the original one because I knew the only way petrol could get into the oil was through the pump.Microscopic damage of the pump piston (17825/17)

Photographs taken with a microscope with approx. 200 x Zoom.This scoring/pitting of the material enables petrol to be transferred to the engine oil content. After heating, the vapours from the fuel travel to the combustion chamber through the crankcase ventilation system and here they enrich (whenever and however intensively) the injected mixture. The system shortens the injection time and the injection time is so short that the injector needle cores hardly open and close and cylinders #2 and #3 start to misfire. This is because they receive the richest mixture based on the fact that the crankcase ventilation system to these cylinders has the shortest path to travel.

Komentáře (0)