Last year we told you about winter starting issues that people had and particularly on diesel engines. Now, this year we are starting to receive many typical questions on what are the correct diagnostic procedures for cold-weather starting issues on different car models. This blog article focuses on this topic.

!WARNING! NEVER try to improve cold cranking by adding small amounts of petrol! Today's diesel engines are equipped with "Oxidation Catalysts" and particle filters. The Catalytic Converter and Particle Filter may sustain severe thermal damage during regenerations when post-injection of fuel occurs and if the diesel fuel, in addition, contains petrol because diesel engines work with excess air. Apart from this issue because petrol doesn't have sufficient lubricating properties such fuel combinations will over time damage the high-pressure pump of modern Common-Rail engines.

It doesn't matter what vehicle you have in front of you. Based on the engine system you always have to verify the most important "vital functions" or in other words "physical preconditions" that every diesel engine should have (especially in winter) for correct starting.

When repairing a difficult starting condition you should always measure the following at the same time when cranking the engine with the starter:

The presence of fuel in the fuel tank is just not enough to say the fuel system is OK. The fuel path has to be free without any flow restrictions or resistance. All these conditions become even more complicated on diesel engine systems without a fuel supply pump in the fuel tank. A fuel filter that hasn't been replaced for a long time may increase fuel flow resistance. During the winter months, these filters will create much higher flow resistance to the diesel fuel because as the temperatures drop diesel fuel begins to gel and form paraffin crystals in some areas of the fuel circuit. During summer months there is no issue but in winter diesel fuel will stop flowing in the supply line or will even break up and create gas bubbles in the fuel. The best time to replace fuel filters that have regular servicing intervals is before winter.

Even if the filtered diesel fuel manages to travel from the fuel tank all the way to this point we can't consider this a success. The fuel injectors may inject lower quantities of fuel into the engine and this could be for a number of reasons. Let's leave aside the possibility that the fuel injectors could be worn or defective. Even an injector in the best condition doesn't have to inject the correct fuel quantity if the Air Flow Quantity Sensor is going to be contaminated or deteriorated or due to a defective Fuel Temperature Sensor. The sensor provides information to the control unit that the fuel is cold (higher viscosity) so that the engine control unit can adjust the longer opening times of the injectors for starting compared to when the fuel is warm. An engine with a similarly unclear and tricky fault will require several repeated cranking attempts before it starts and stays running.

Diesel engines operate on the principle of heating air where the volume of the intake air is quickly compressed to such high pressure that the air heats up so much that the injected diesel fuel ignites itself without any external source of ignition. The only circumstance that improves the compression temperature is preheating (see next paragraph), which should be active during cold engine starting. The engine will be reluctant to start to a point of no-start condition in winter if the compression is insufficient (high cylinder wear due to high mileage), fuel is not atomized, summer fuel is used or the preheating system is not working.

Engine cranking speed on diesel engines is No. 1 priority because the rotating speed of the crankshaft has a direct influence on reaching the required diesel fuel ignition temperature. If the piston compresses the air volume too slowly the required temperature will not be reached and the engine will not start because fuel ignition at lower temperatures is difficult. This is why it's a good idea to test the battery, the engine cranking speed and the starter current draw before the winter season. Very often even the best new battery doesn't have enough power to turn the starter that has increased play in the pinion shaft bushings. If the pinion enters the flywheel ring gear at a different angle and exerts resistance to the electric motor it will reduce the starter power to a point that it won't have enough energy to crank the engine properly.

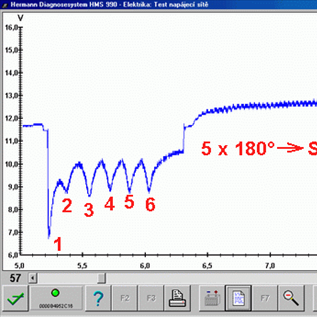

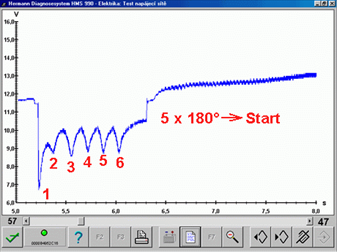

Engines with particle filters activate the preheating system even during very hot summer days. So the proper performance of the complete preheating system is not only essential for cold weather conditions. It is also required for restricting high levels of soot generation during cold engine starting and during the complete engine operating temperature build-up phase to reduce the unwanted DPF filter saturation levels. The best tool for analyzing the preheating system is an oscilloscope. It can reveal the cause and not just the consequences of insufficiently heated glow plugs.

The majority of motorists read globally similar advice before winter more as a promotion to sell everything that is lying unnoticed in stock and the best time to get rid of everything is before Christmas. Very often many people are surprised that after they buy a new battery their car doesn't start when the first frosts arrive.

FCD services use a different diagnostic method. This is a complex mapping method of all monitored areas that is called a MULTITEST. A data storage oscilloscope is used for this task. "This can reduce the "winter check” time considerably and will include all the required data!" With the Multitest it takes only 10 to 20 minutes to find out such details that take half a day with usual standard tests. The test results include specific information about all the conditions necessary for a successful cold engine start.

It does make sense to have your car tested using a Multitest that is focused on winter conditions, if you don't want to lose money by buying a new battery when your battery is still in a good condition. Also, if you want to find out what can jeopardize the mobility of your car during winter including the random replacement of expensive parts using a trial and error method. On "petrol" engines everything is much easier but nevertheless, well-prepared and tested cars before winter will have much higher chances of surviving demanding weather conditions.

We recommend proceeding according to the following articles available in the Academy section of the FCD.eu website to eliminate situations happening to your customers similar to the starting issues experienced by the owner of a Škoda Rapid during the whole winter that included the unnecessary glow plug replacement (https://www.fcd.eu/blog/post/1979).

We describe how and what can be verified with this ingeniously simple Multitest, together with Fault Location methods in the below-mentioned article that is free for your viewing for a period of 14 days. In the article, you will find procedures including videos that will guide you on how to transfer these tests into the everyday workshop routine. After this Free period, everything will be accessible only to those with paid access to the FCD.eu website.

Thank you for your time in reading this and we wish you a nice winter without any starting issues!

Your FCD team

1. Weak battery 2. Restrictions in fuel supply (fuel filter) 3. Lower compression 4. Deteriorated airflow sensor 5. Preheating 6. Fuel temperature sensor

Within 1/2 hour we can record all data and during another hour we know everything about systems responsible for cold starting.

Professionals that have the knowledge to work with traces from an oscilloscope have the ability to read from the shape of these traces and from the el. current and voltage development values over time to recognize which system may cause a problem in winter. Such a quick test doesn't cost much because of its simplicity. The actual measurement isn't that precise in detail but its complex summary because of the dynamic details can reveal where a problem may appear in winter.

The current clamps measuring the current draw during cranking are placed around one of the battery power cables.

The Multitest is based on "speed" and not on accuracy. So we only connect what can be connected quickly and doesn't take up too much of our time.

Kompletní informace na toto téma

a mnoho dalších informací najdete pod odkazy níže.

Vyzkoušejte si nás nezávazně na 14 dní zdarma.

Vyzkoušet 14 dní zdarma

Komentáře (0)

Vložit soubor