Diagnostický případ

Mixture too lean and too rich

Informace o vozidle

| VIN: | TMBBE41U8Y2292936 |

| Výrobce: | Skoda |

| Model: | Octavia/Octavia Tour |

| Rok výroby: | 1999 |

| Kód motoru: | 2,0 |

| Typ motoru: | AQY |

| Výkon (kW): | 85 kW |

| Převodovka: | Manuální |

| Palivo: | Benzín |

| Najeto: | 263 704 km |

Jak se závada projevuje

Nefunguje / funguje nesprávně. MIL ON

Jak často se závada projevuje

- Trvale přítomná závada.

V jakém systému se závada vyskytuje

- Motoru.

- během jízdy

- [P0171] System Too Lean Bank 1

- [P0172] System Tooo Rich Bank 1

- trvalá závada

- sporadická závada

Doposud provedeno bez úspěchu

Lambda sensor repair: https://www.fcd.eu/story/15483Závěr

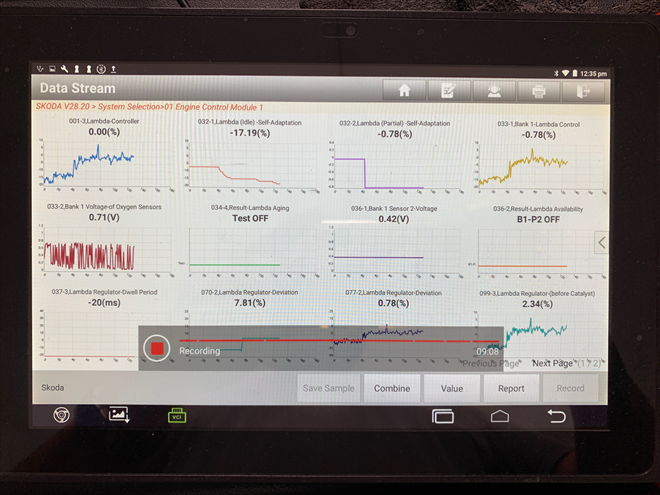

VOZIDLO JSEM OPRAVILRepaired. The engine was lacking a sufficient amount of air at idle (due to deposits in the air supply line of the AIR MIX system). The second issue was a problem with a reduced or incorrect fuel pressure value under load (due to a deteriorated fuel pressure regulator diaphragm).

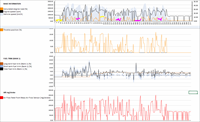

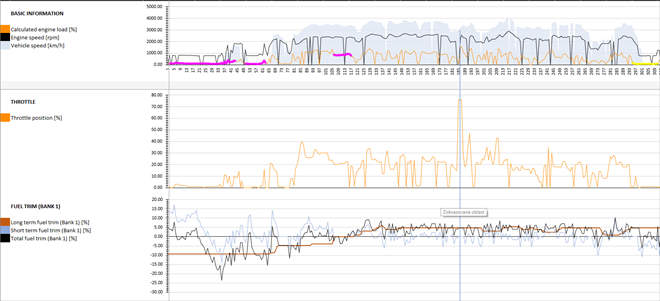

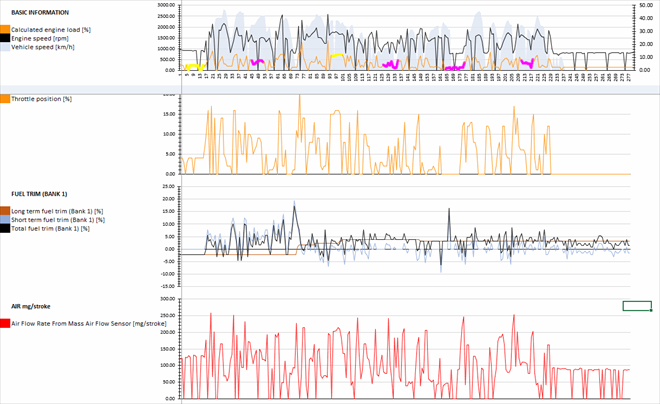

The new airflow sensor didn't help. The causes of the second fault were quite complicated, but simulations helped. These issues require enrichment of the mixture under load (max. fuel pressure) and leaning of the mixture at idle (limit the fuel pressure through a regulator). We didn't solve the idle issue by modifying the fuel pressure. This was fixed by removing the resin deposits in the supply line of the AIR MIX system. The missing air quantity was confirmed by increased adaptive values of the idle control valve.

The AIR-MIX injection system air to the individual injectors is supplied by an intake duct into which the crankcase breather is vented. I must note that the breather system isn't perfect. The oil vapour separator doesn't work very well on this system. It allows the oil to reach both the heated foil of the airflow sensor and the AIR MIX system, where the hard resins from the oil over time create deposits. The largest deposits are near the #1 cylinder fuel injector. The resin deposits increased over 200 000 km, restricting the airflow through the AIR MIX system. Therefore the amount of air flowing around the injectors is lower to the point where the mixture becomes "richer" at idle and the engine control unit keeps adapting the mixture towards the lean direction (additive fuel trim = –17%). Hence this generates the "mixture too rich" fault code.

It took us quite a while to figure out that the opposite fault code, "mixture too lean", was generated when a load was applied to the engine. This was caused by a deteriorated fuel differential pressure regulator vacuum diaphragm that didn't have the required flexibility anymore. The fuel pump can generate the required pressure, but the engine control unit was forced to adapt the multiplicative fuel trim and enrich the mixture because the deteriorated diaphragm was limiting the required fuel pressure under engine load by as much as +20%!

Komentáře (0)