If it wasn't for this specific fault, we probably wouldn't have discovered this diagnostic option now. In the live values, the Mercedes 220 d didn't complain about the lower performance of cylinder 3 ("correction fuel delivery for uniform idle"), but from an air intake point of view, it was cylinder #3 that was affecting the engine's operation so much that immediately after starting the vehicle, the engine control unit switched to failsafe mode. The car had no power and it was dangerous to overtake even a driving school with it.

If the engine does not intake enough air according to the log recording, the most likely cause for any mechanic is the "airflow sensor" or the "EGR valve".

However, if a more alert mechanic's eye notices a high Lambda value, he will realise that it cannot be excessive backflow of exhaust gases, despite the fact that such a fault code sometimes appears in the fault memory!

Replacing the airflow sensor by one of the previous workshops did not fix the fault, the condition remained the same as before the repair. No anomalies were found in both EGR systems (high pressure/low pressure) either.

The main clue was the observation that the engine roars more at idle than is usual for Mercedes with this engine. And since the sound is nothing more than pressure waves, we wanted to test for the first time what these sound waves (intake roar) look like on an oscilloscope. We used the intake pressure sensor, which is located in the intake near the intake valves.

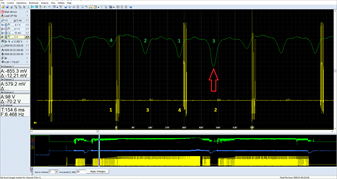

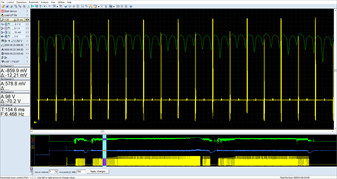

Having established that the pressure wave on cylinder 3 is indeed much smaller than on the others when the valves overlap, we wanted to see if the pressure anomaly on cylinder 3 also transcribes into the intake airflow sensor signal. After all, air is the carrier of pressure waves and the sensor could register this.

It did, and since pressure waves travel at the speed of sound, the airflow sensor registers the faulty cylinder with a delay of less than 3 milliseconds.

Now it is clear why the control unit complained over and over again about a "faulty airflow sensor", but the message should have been formulated by the developer of the Mercedes onboard diagnostics in our opinion less specifically. We at FCD Garage would have selected this fault message, "Measured air quantity is unreasonably low." There should be instructions in the Mercedes manual on how to proceed: for example, "Pay attention to the Lambda value in relation to the amount of fuel or exhaust gas return and all components along the air path, e.g. valve train, intake and exhaust manifolds for their free flow, including the throttle bodies."

This is a free tutorial for beginners with logical diagnostics. If you want to add your own comments, you must at least register here: New Register. If you become a paying registered reader, you can study these topics in depth in our Academy section.

Even if this was to be true, the pump replacement most probably didn't have any influence on the cylinder #3 fault. It was necessary to search somewhere else....

The cause of the engine roar is due to differences in the pressure waves during the A/F charge replacement on cylinder #3, which also affects the air intake signal (green). Green numbers indicate cylinder A/F charge replacement, yellow numbers indicate the cylinder firing order.

The roaring sound captured by the oscilloscope in the traces indicates a mechanical defect in the timing system or on the piston.

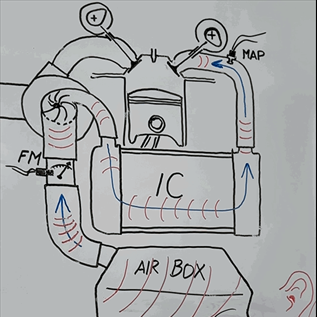

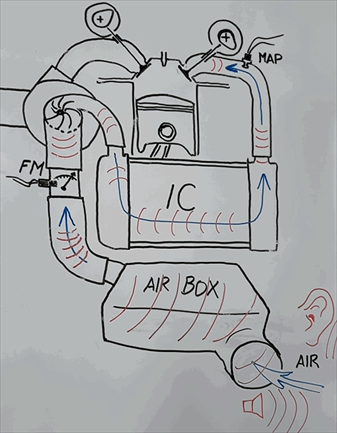

The spark for the measurement was an audible, unusually loud roaring sound from the intake... The air flows through the intake into the engine (blue arrows), but it is also a transport medium for pressure waves (red waves), and therefore sound, travelling in the opposite direction. The sound travels at a speed of 343 m/s in all directions, and the effects of these waves, originating from the intake valves, can be seen on the signal of the intake air volume sensor, over one metre away from the valves, with a delay of approximately 3 milliseconds. All diagnosticians can now make their work easier because the valve train function can be monitored in near real time on the intake airflow sensor.

Komentáře (0)

Vložit soubor