The FCD Garage request was that the remote diagnostics include more values than offered by the EOBD protocol.

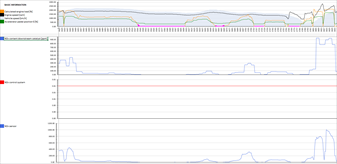

The programmers from DevCom, the supplier of our FCD Loggers, started to program a mix of EOBD data with OEM diagnostics data in a single recording. The most relevant values are sampled more quickly (at 2x per second) and the others are sampled at a slower rate. This allows us to record a total of 56 of the most relevant values in a single recording.

The choice was aimed at the most critical systems such as the DPF, where we wanted to know the calculated and measured DPF soot saturation, the differential pressure, etc. We also required values about AdBlue urea injection into the SCR catalyst, differential pressure sensor or NOx sensor values.

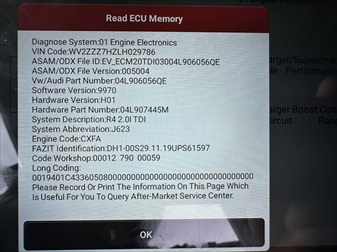

The first guinea pig is the VW Group, which has about 4,000 ASAM codes for diesel engines alone. These ASAM codes can be divided into about 30 groups according to different criteria (e.g. EU5/6, engine capacity, etc.).

The procedure is that the FCD Logger first downloads the updated software for VW Group cars. After that, you can go for a test drive and monitor the DPF parameters. If these parameters are not available for your specific model you will need to connect a scantool with OEM software and read the identifying information about the engine ASAM protocol and its version and send it to us to the following email: fleis@ihr-tech.cz. The implemented modifications will be included in your logger's next software update allowing you to view and log the values. Please understand that we cannot include the full coverage of all variants any faster by any other means than by collecting information about ASAM protocol versions.

Take a look with us at the first two successful attempts at logging mixed data (VW Transporter T6 and T7), where the sampling rate is specifically defined selectively for each value separately so that the data logging still makes sense with a total of 56 parameters.

DevCom programmers have successfully combined EOBD and OEM data into the FCD Logger. We then modified the Logger to sample the necessary data faster (up to 2 times per second) and the unnecessary data at longer intervals. The FCD Loggers sampling rate isn't influenced by the number of logged values. The important are logged faster and the less important at slower rates. The good part is that all values are logged!

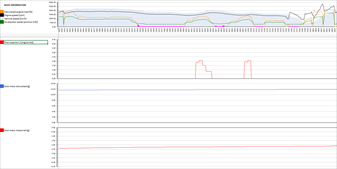

The DPF differential pressure is next to the theoretically calculated and measured soot content probably the most important information we need from vehicles with diesel particulate filters.

The DPF differential pressure is one of the most important information related to the DPF regeneration process.

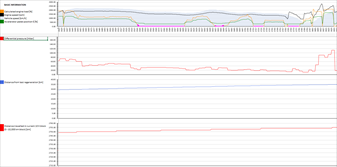

Essential information for assessing the condition of oxidation catalysts that we evaluate during regeneration.

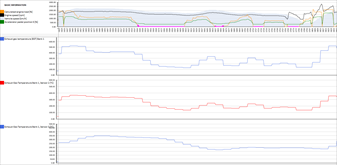

From activity to urea pressure to the Nox content in the exhaust gases...

This data already works on the VW T6 and T7, but also on other models. More models to be included require your help. We can't get that many different ASAM protocols so quickly on our own. Can you help and send us logs from other VW diesel engines?

To be able to add VW Group data to the FCD Logger protocol and mix it into the EOBD recording in a short time, we need your help to speed up the implementation process. We can't collect so many different types of VW engines and log them ourselves at the FCD Garage. We need a log from the FCD Logger (or EOBD scantool) and the information from VW diagnostics about the engine control unit, as you can see in the picture. Please send by discreet mail, or here through the comments.

Excel file for download...

Komentáře (0)

Vložit soubor