Customers that have problems with particle filters and the associated illumination of the DPF warning light or the engine MIL light very often hear the term "clogged" filter.

Hearing from a mechanic without any previous testing about a "clogged" particle filter with soot is evidence that he doesn't have sufficient experience. As the particle filters heat up they considerably change the flow capacity of the exhaust gases through the filter. With the increasing temperature, "this can" be interpreted from the measured backpressure values by the differential pressure sensor that the "particle filter is saturated by soot".

But is the particle filter being saturated/clogged by soot or not? A better question would be, "Is the engine generating so much soot that it clogs the filter prematurely?"

In general, the engine control unit guides itself when evaluating the efficiency of the particle filter (DTC P2002) using several parameters, while every single one can set a DTC:

If the mechanic is convinced from at least three test drive Log recordings that the particle filter backpressure value rises quickly, he will run into another major question:

Chicken or egg? Is the filter saturated by a smoking engine or is the control unit only assuming that the filter is clogged because it's misinterpreting the information provided by the newly installed components?

In our emission video courses that are available online on the FCD.eu web portal, we teach the mechanics of how to handle issues related to the DPF system. We can determine if the engine is smoking within 10 minutes and without removing any part. You just have to know how to monitor exhaust gases with other emission test equipment. Thanks to physics and chemistry, we know what needs to be done first.

Link to online emission video courses: https://www.fcd.eu/course/online/10

If the control unit reports a frequently saturated particle filter or that the filter efficiency is below the threshold the cause could be a smoking engine producing large soot particles. Unit Injector and Common Rail engines shouldn't generate large soot particles. Therefore the optical-type smoke machine will test the raw emissions for "LARGE SOOT PARTICLES". An optical-type smoke test machine will show if the filter's quick soot saturation is caused by the engine or not. Under certain conditions, we then connect the smoke machine to the exhaust gas outlet pressure line in front of the DPF filter.

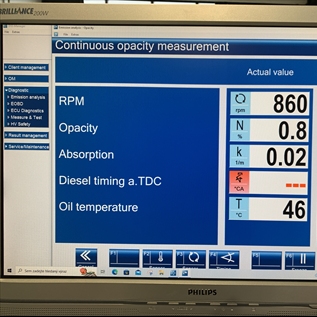

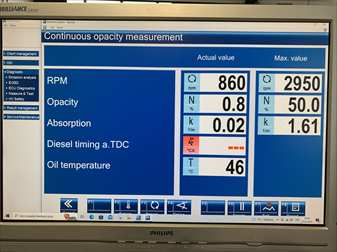

The value of k = 1,61 [1/m] doesn't belong to dramatic high values and corresponds with mileage of over 300 000 km of a looked after engine. Nevertheless the same engines without a DPF filter on a new vehicle achieved values 0.7 to 1.3 [1/m] (we have even seen values of 0.3 "w/o a filter"!). The European maximum given by law is 1.5 [1/m]. The values shown in this image are values "IN FRONT OF THE DPF FILTER". That means they are raw. Behind the filter (this filter is clearly cracked) the value is 0.29 [1/m]. Under normal circumstances, a fully functional filter wouldn't show any exhaust smoke emissions or they would be within the measurement error values of 0,02 [1/m] etc.)

When analyzing DPF problems the vehicle should be completely tested with both machines. The older generation "smoke machine" working on a principle of light absorption detects larger soot particles using the light absorption method. The latest particle counter detects invisible micro soot particles using a method of electrostatically charging particles that pass through a sensor, and then measuring the current caused by the charged particles leaving the sensor. These small particles generated by new design engines with Common Rail and Unit Injector fuel injection cannot be detected by the older light absorption smoke testers and yet these particles are more dangerous than the large particles. With the particle counter, we can detect not only a cracked filter but also aftermarket filters with higher porosity. We can measure all the necessary values from the hoses in front and behind the DPF filter. All this is without the risk that the measurement is going to be influenced by deposits accumulated along the complete length of the exhaust system and eliminating possible measuring errors in the exhaust tailpipe.

Kompletní informace na toto téma

a mnoho dalších informací najdete pod odkazy níže.

Vyzkoušejte si nás nezávazně na 14 dní zdarma.

Vyzkoušet 14 dní zdarma

Komentáře (0)

Vložit soubor