When a 10-year-old particle filter after 500 000 km stops working, it should be cleaned or replaced by a new component. Part of the new component is a Certificate of Conformity (CE) that should protect you against poor quality components, that don't work properly or can even damage the engine. There are several possible risks why the aftermarket DPF filter won't work on the vehicle. This article describes all the possibilities.

An associated workshop asked us to analyse a problem on a Toyota Rav with a new aftermarket DPF filter (with a CE certificate) and installed third new OEM differential pressure sensor. Nevertheless, the customer keeps returning after a few hundred kilometres with the MIL light On and a stored DTC "Particulate Filter Efficiency Below Threshold" (P2002).

Our analysis concluded that the mechanic's repair attempts bypassed the cause of why this DTC activates, which is the aftermarket DPF filter. Not because the filter itself, is malfunctioning, but because the filter's secondary physical properties (backpressure) probably differ too much from the OEM DPF filter.

The engine ECU evaluates the DPF filter as having low efficiency, leading to the MIL light's illumination and activation of the limp-home mode with reduced engine power.

The Toyota OEM DPF filter costs about 1 000,- EUR if you return the old part. The mechanic, in good faith, installed an aftermarket filter that cost almost the same and a brand that the mechanic had a good experience with. None of the vehicles returned to him with a problem.

In our case, it looks like this aftermarket filter cannot be used on this Toyota, and requiring the installation of a new OEM filter recognisable by the engine ECU software. However, Toyota accepts for returned parts only a Toyota-manufactured filter. Otherwise, the customer has to pay an extra 420,- EUR for the new OEM filter. The reason is the different content of the precious materials in the old OEM filter that can be recycled and used again to manufacture new filters. Unfortunately, the mechanic scrapped the old Toyota filter.

Are the attached Conformity Certificates acknowledging that the part complies with an OEM part worthless similar to the MOT certificates?

From experience, we can see insufficient thoroughness in approving spare parts for purchase. The DPF filter must not only "filter" correctly, but the filters catalytic layer must "generate sufficient heat reaction" to ignite and burn soot, and the filter's "internal resistance" when the hot gases pass through the filter shouldn't differ too much from the OEM filter. If the internal resistance under changing loads, temperatures and engine speed is higher compared with the OEM filter, the engine ECU considers this as a command to activate the particle filter regeneration and burn the accumulated soot. This is how the regeneration cycle works.

Not quite. The higher back pressure results in earlier regenerations than the usual 600 km, because the engine ECU considers the higher backpressure values as increased filter saturation. If the shorter interval repeats several times, the vehicle gives a warning through the MIL and DTC. This is not just because of the short intervals, but also for the following three possible reasons:

The MIL can repeatedly illuminate due to the "non-conforming spare parts", not only because of the mentioned reasons. The engine control unit can activate the DTC P2002 – Particulate Filter Efficiency Below Threshold if the dynamics of the above-mentioned parameters differ from the expected dynamic values (time monitored) stored in the calibrated maps in the engine control unit.

We think the main blame goes to careless work and the neglect of compulsory authorisation procedures by the approved certification institutions that "certify" products. The situation in the automotive spare parts market in the last few years is very sad. The business with spare parts is so lucrative that low-quality products receive CE approvals despite that they shouldn't have been approved.

Why is something being sold if it doesn't work on a vehicle? Association of Repairers and Emission Testers (ASEM) initiated a campaign supported by Norway Grants and the Ministry of Environment, "Cure a Creature" (https://uzdravpriserku.cz/), that should alert about the conditions and also uncover offenders surrounding the Ministry of Transport that is somewhat associated with the problems that the owner of the Toyota Rav is having for the last half a year.

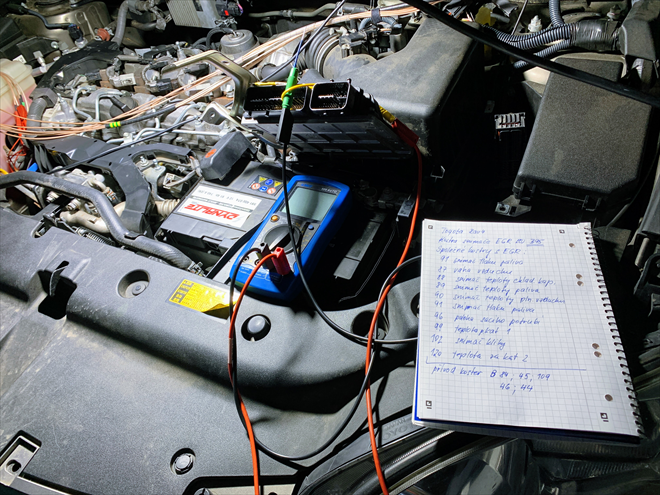

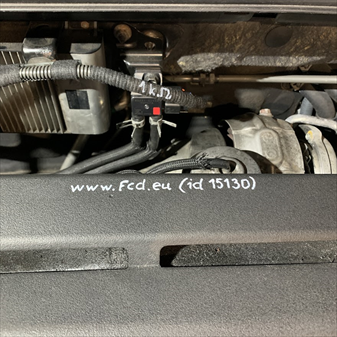

If the DPF filter parameters differ from the OEM filter, the engine ECU will have problems with this, which can lead to the stopping of the complete vehicle. At this point, the mechanic is helpless. The image is related to a different "challenging" phase of fault location ("wandering/poor" ground of the EGR valve position sensor).

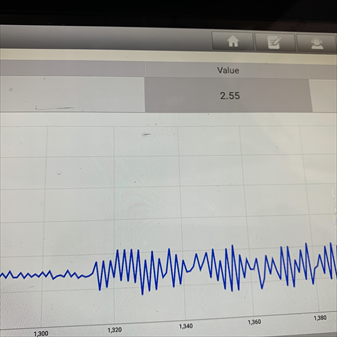

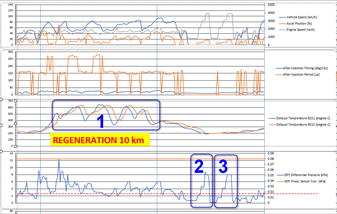

The signal oscillations of the differential pressure are caused by shocks generated by the operation of a 4-stroke engine. The question is if the intensity of these shocks that distort the backpressure values monitored by the ECU is determined primarily by the shape of the particle filter, the filtration liner, its response to the hot exhaust gases, flow capacity or flow resistance through the channels. If the replacement DPF filter affects the signal wavelength, the control unit may interpret this as higher backpressure in specific rpm ranges and, as a result, will trigger regeneration because it thinks the filter is full of soot. But the filter doesn't have to be full of soot at all. This is why we need to dampen these dynamic pressure pulses. We used a porous dampening foam that we inserted into the hoses in front of the sensor.

Before, during and after regeneration, the log offers enough information about the mismatch of the aftermarket part with the original. 1) Information that only a minimum amount of soot is burning in the filter. If there is any soot at all... 2) Information about backpressure values on an "empty" (regenerated) DPF filter with a partially closed EGR valve. 3) Information about backpressure values on an "empty" (regenerated) DPF filter with an open EGR valve. These clues from experience will lead to the activation of the DTC P2002 – Particle Filter Efficiency below the Threshold.

The input hoses include the porous deadening foam (which isn't visible). It isn't recommended to solder in series or in parallel between wires different resistors to modify the signal to match the stored values in the engine ECU memory. From experience, we know that everything has an influence on everything, and if we lie to the ECU, telling her something that isn't, in fact, true may not pay off. As an example, dangerously high pressure may build up in the filter for some reason, and thanks to our artificially distorted values, the ECU can incorrectly consider the pressure as "safe" and won't take any action. This could result in engine damage and even a fire risk.

Experimenting is possible, but always transparent with reasoning why the "simulation" was applied. In this case, we reduced the maximum backpressure so that we could determine which reason was responsible for activating DTC P2002. If it's the temperatures on the T2 sensor during regeneration or higher backpressure. This is a reminder that the modification is for test purposes only, and the vehicle shouldn't be returned to the customer like this.

Kompletní informace na toto téma

a mnoho dalších informací najdete pod odkazy níže.

Vyzkoušejte si nás nezávazně na 14 dní zdarma.

Vyzkoušet 14 dní zdarma

Komentáře (0)

Vložit soubor